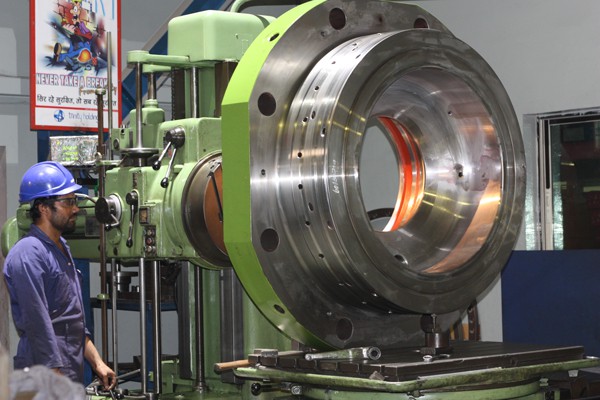

Conventional Machining

Trinity is a leader in the mechanical service industry with over 20 years of experience in machining and fabricating mechanical components. The conventional machining facilities and the infrastructure of the machine shop enable it to handle a wide array of repair and re-conditioning of mechanical components from almost all industries.

The company takes pride in its ability to reverse engineer products and in some cases provides an improved life span for components through its dedicated and highly experienced work force.

All conventional machining jobs are carried out by highly skilled personnel using the time trusted machines.

Conventional Machining Facility

Trinity’s state of the art facility comprises of the following conventional machines:

*Spiral bevel - 600 mm diameter

Trinity's skilled and experienced engineers are able to reverse engineer components from old worn/broken samples to manufacture new ones. Regularly manufactured components include:

- Oil field components

- Pump components

- Dredging components

- Hydraulic cylinders

- Gears

- Sheaves

- White metal bearings

Common dynamically balanced components:

- Crankshafts

- Drive shafts with universal joints

- Rotors & rotor assemblies

- Fans

- Impellers

- Blowers

- Other rotating equipment

-

Conventional Machining

-

Conventional Machining

-

Conventional Machining

-

Conventional Machining