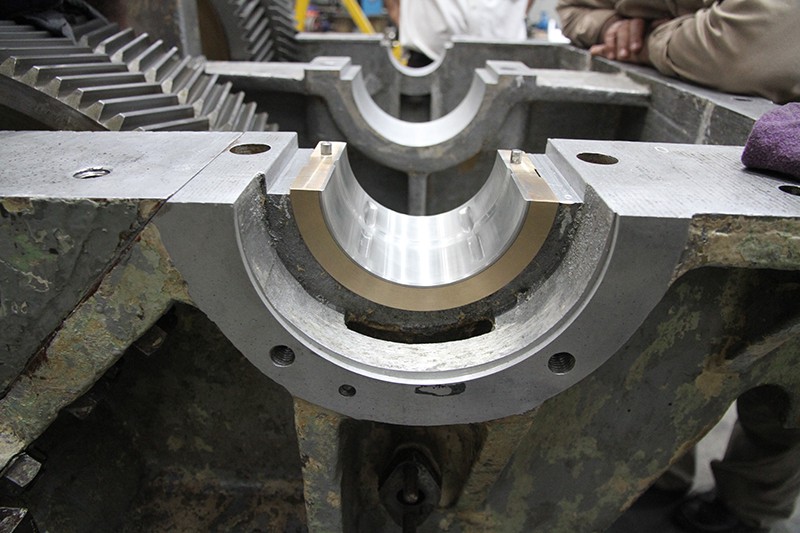

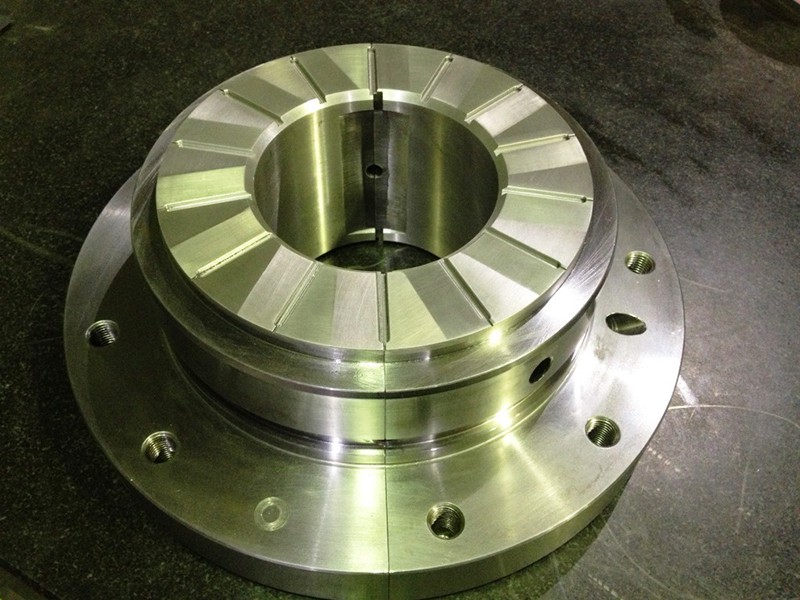

White Metal Bearings

Trinity offers specialized white metal bearings manufacture, repair and refurbishment for OEMs and operators of rotary equipment. Trinity’s team has the capacity to manufacture and repair bearings of various sizes, types and quantities. All types of white metal lined components can be manufactured or repaired for industries such as hydrocarbon processing, power generation, turbo-machinery, steel rolling mills, power transmission and aerospace. Composition analysis and ultrasonic bond testing is available in order to ensure highest quality in accordance with industry standards.

Services offered by Trinity’s white metal specialists include:

- Manufacturing

- Repair and refurbishment

- Reverse engineering

- Technical consulting including bearing design

- Failure analysis

We offer manufacturing and repair services for the following types of bearings among others:

- Stern tube bearings

- Fixed profile thrust and journal bearings

- Tilting pad thrust and journal bearings

- Turbine and generator liners

- Vertical bearing assemblies

- Horizontal bearing assemblies

- Balance piston seals

- Hydrogen seal rings

- Mechanical seals

- Labyrinth seals

The white metal team is supported by the following facility capabilities to provide quality service to our customers:

- Centrifugal casting

- Gravity casting

- Thermal spray

- Hydraulic pressure testing

- Hydrostatic pressure testing

- Large machining capacity

-

White Metal Bearings

-

White Metal Bearings

-

White Metal Bearings

-

White Metal Bearings